How to use the Axle Press on Your Pinewood Derby Car

How to use the Axle Press on Your Pinewood Derby Car

Most axles are NAILS! They are not straight and more than likely never will be unless they are corrected.

The Pro-Axle Press Pinewood Derby Tool is designed to straighten and round the nail axles used in many pinewood derby car kits. It also can be used to taper the axle head to reduce friction. Accurate axles lead to faster racing!

The Pro-Axle Press will improve the speed of your pinewood derby car by performing three critical procedures on nail type axles:

- Axle Straightening - Ensures accurate wheel tracking by creating absolutely straight axles. Improved wheel tracking equals greater speed!

- Axle Rounding - Ensures accurate wheel rotation by creating absolutely round axle shafts. Improved wheel rotation equals greater speed!

- Head Squaring - Reduces friction by accurately squaring the axle head to the axle shaft.

When it is necessary to purposely bend an axle (to raise a front wheel or make an alignment adjustment), the Pro-Axle Press serves as a handy clamping device for holding the axle while making the bend.

The Pro Axle Press has different opposing sides. One side is smooth for squaring the axle head. The other has a recess made into it to form the head into a taper.

Insert an axle into the chuck of a drill. Use a file to remove the burr under the nail head and any crimp marks on the axle shaft.

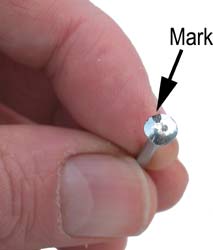

With a marking pen, make a mark on the edge of the axle head.

Fully insert the axle - point first - into the Axle Press. Rotate the axle head such that the mark is located at the top (12 o'clock). Close the press. Place the Axle Press on a solid surface. Hold it in place and strike the top of the press 4 to 6 times with a hammer. Don't strike too hard - medium strikes are fine.

Open the press and rotate the mark to the 4 o'clock position. Repeat the above step. Rotate the mark to the 8 o'clock position and repeat.

Lay the press on its back (axle head upward) and strike the axle head 2 to 4 times. This ensures that the axle head is square to the axle shaft.

Insert the axle in the other side of the tool. The head should now be on the side with the recessed hole. Lay the press on its back (axle head upward) and strike the axle with light to moderate force 2 to 4 times. This will taper the axle head.

Polish the axle to the desired finish.

Pinewood Derby Racer's tip: To accurately bend an axle for alignment or for a raised wheel, insert the axle into the Axle Press with the head extended 3/8 inch from the tool. Place the Axle Press in a clamp or vise. Gently tap the axle with a hammer until the desired bend is achieved.

The Pro Axle Press reduces friction! By creating a straight axle in an accurate hole on the body, the wheel will work in the most efficient manner.

Axle Press

Watch this video on how to use the Pro Axle Press to

straighten the axles on your pinewood derby car.

Axle Press Video Transcript

The Pro Axle Press is designed to improve speed and performance of your Pinewood Derby car by correcting the nail type axles that come with most kits. The Pro Axle Press is a 2 piece jaw specifically designed for straightening both the length of the nail and for squaring the head of the nail to the center line of the body.

First, we take our nail or axle, we deburr it and remove any of the crimp marks from manufacturing. This will ensure we have a straight and correct axle going into the press.

Next, with a marker, we mark the 12 o'clock position on the axle for indexing. Insert the axle into the Pro Axle Press with the mark in the 12 o'clock position. With our hammer we firmly strike 3 to 5 times.

Now we rotate this index mark to the 4 o'clock position. Repeat. Rotate the index mark to the 8 o'clock position and repeat for a 3rd time for straightening the axle length.

Upon completion lay the tool on it's back and firmly strike the axle head 2 to 3 times to square the head of the axle to the center line of the axle shaft.